When it comes to metal manufacture, one of the most critical equipments in the market is the press brake. A press brake is utilized to form and flex metal sheets right into numerous forms and angles, making it essential in producing markets such as vehicle, aerospace, and building and construction.

China has become a leading hub for press brake suppliers, providing a series of devices developed to satisfy the diverse requirements of the metalworking market. Business such as WEIYA go to the leading edge of this market, using a large variety of hydraulic press brakes, electric press brakes, and CNC press brakes. These machines are created with innovative innovation and ingenious design to make certain high performance and reliability in demanding manufacturing settings. Hydraulic press brakes, for circumstances, are recognized for their enormous power and capability to handle thicker products, making them suitable for durable applications. On the other hand, electric press brakes are admired for their energy efficiency and reduced operating expenses, which appeal to services focused on minimizing their carbon footprint.

One can not ignore the importance of shearing devices in metalworking together with press brakes. Both devices play an important duty in preparing metal sheets prior to they are refined with a press brake, making certain that the first cutting fulfills the specific needs for succeeding flexing procedures.

The versatility of CNC machines extends past press brakes to incorporate numerous other types of metal cutting devices. CNC (computer numerical control) technology permits the automation of highly precise jobs, making it less complicated to generate repeatable results that fulfill rigorous top quality requirements. For larger operations, having a tandem press brake can offer numerous advantages, enabling producers to handle longer sheets of metal and enhancing total effectiveness through continual procedure. Big press brakes bring additional capacities to the floor, making them ideal for managing larger parts typically located in commercial applications.

With the expanding emphasis on effective production processes, the popularity of servo motor press brakes gets on the surge. These machines integrate the power of hydraulic press brakes with the accuracy of electric ones, offering a hybrid strategy that optimizes performance, minimizes power intake, and minimizes deterioration on parts. This technology is especially helpful in industries that require complex flexing procedures and where tolerances are crucial. The option of a press brake, whether it be hydraulic, electric, or an extra innovative CNC model, usually depends upon the specific application and the kind of materials being processed.

In instances where firms are aiming to reduce expenses without compromising quality, an NC press brake can be a viable alternative. While NC versions might not provide the same degree of automation as their CNC equivalents, they still offer reputable performance for many common applications. For makers that prioritize high accuracy and automation, investing in a CNC press brake is often the finest choice, specifically as the competition of the manufacturing industry comes to be much more obvious.

Firms like Amada, Trumpf, YAWEI, and WEIYA have actually developed themselves as leaders in the press brake making room in China and past. The dedication to top quality and efficiency by these suppliers offers customers the guarantee that they are spending in equipment that can stand up to the rigors of everyday usage while delivering the accuracy required for successful metal construction.

As markets advance, so do the technical innovations within the world of press brakes. Functions like the E21 press brake control system are becoming increasingly usual, using intuitive procedure and boosted programs capabilities, which subsequently minimize setup times and enhance performance. These developments also assist in simpler driver training, enabling new team to end up being competent with machine procedures quicker, consequently enhancing the firm's overall outcome and performance.

In addition, investments in modern-day press brake technologies expand beyond simply the machines themselves. Combination with smart production solutions, such as the Internet of Things (IoT), makes it possible for real-time tracking, anticipating upkeep, and insights into functional efficiencies. This connectivity permits producers to enhance manufacturing schedules, expect machine downtime, and make data-driven choices that align with service objectives.

Overall, the world of press brakes and shearing makers is both vast and complex, driven by innovation and need for top quality. Each machine plays a vital function in metal manufacture, from first cutting to last shaping. With a multitude of options readily available, manufacturers must thoroughly consider their certain requirements-- whether they need a straightforward NC press brake or an innovative CNC version incorporated right into a more comprehensive clever production structure.

As a CNC machine tool factory, WEIYA specializes in a variety of makers, but its press brakes stand out for their cutting-edge features and straightforward operations. Regardless of whether one is in requirement of a hydraulic press brake or an electric press brake, manufacturers such as WEIYA make every effort to provide alternatives that combine effectiveness with precision.

CNC press brakes are specifically preferred amongst suppliers looking for automation and progressed control attributes. While hydraulic press brakes proceed to control the market, servo and electric motor press brakes are additionally gaining traction due to their reduced power intake and minimized functional expenses.

Shearing devices, including swing beam shearing machines and guillotine shearing machines, are usually used along with press brakes in metal construction facilities. These machines are made for cutting metal sheets with accuracy, working as more info a versatile solution for suppliers needing elaborate and consistent cuts. When incorporated with a press brake, they create an effective duo necessary for changing raw metal right into ended up parts.

Within the realm of metal cutting, QC12K swing beam shearing machines have actually become a staple as a result of their toughness and performance. These devices are made to manage numerous types of products, offering drivers with the flexibility required in a competitive production environment. The combination of a premium shearing machine and a dependable press brake permits producers to simplify their production and offer higher-quality items at an affordable price point.

For those interested in large-scale operations, tandem press brakes are a perfect choice. Additionally, big press brakes frequently come with enhanced features that facilitate safer and extra reliable procedures.

Torsion press brakes have actually likewise acquired attention for their unique layout and functionality, particularly when it involves flexing thicker materials with accuracy. The torsion system allows for adaptability in the flexing process, making it easier to attain complicated bends without distorting the material. NC (Numerical Control) press brakes streamline the operation better, making them an easily accessible choice for workshops looking to boost their capabilities without calling for substantial proficiency.

In verdict, as suppliers proceed to press for boosted performance and performance in metal manufacture, the value of high-grade press brakes and shearing equipments can not be overemphasized. The trip of changing raw metal into functional components through press brakes and shearing equipments highlights the exceptional workmanship and technological expertise that define modern manufacturing.

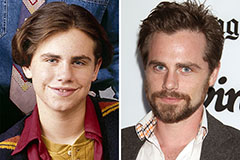

Rider Strong Then & Now!

Rider Strong Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!